-

Shopping cart is empty

-

x

-

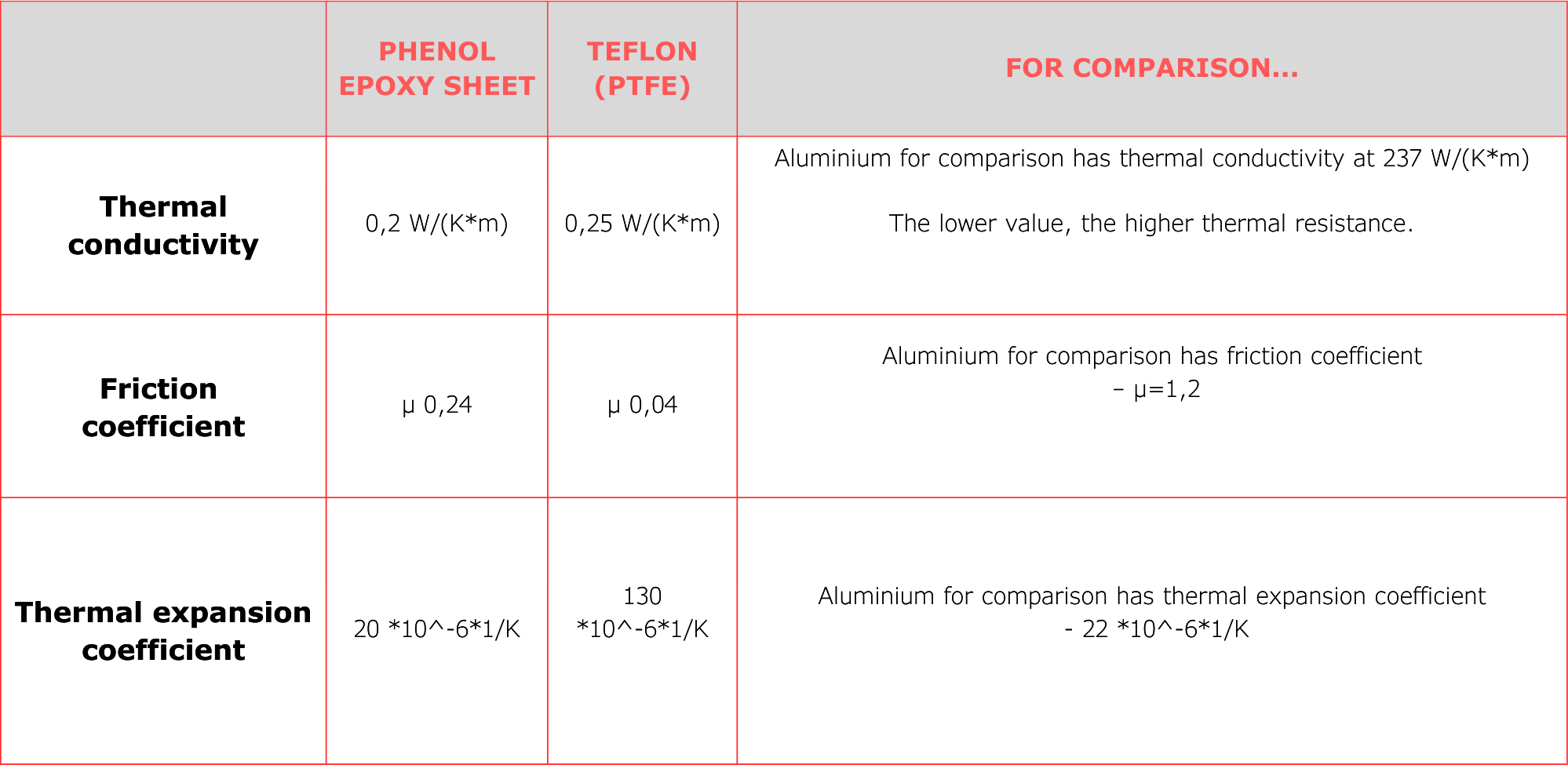

Why phenol epoxy sheet over Teflon (PTFE)?

As you can see, the thermal conductivity of phenolic sheet is slightly better than Teflon.

Phenol epoxy sheet grows in size at the same rate as aluminium does, maintaining the same dimensional relations (eg. port size, port spacing, etc.), where Teflon grows almost 7 times more.

For example:

400 mm long spacer (at 20deg C) will have 400,14 mm (at 90deg C)

Aluminium of the same length will have 400,154 mm (at 90 deg C)

Where Teflon of the same length will have 400,91 mm at 90deg C

Different thermal expansion rate together with much lower friction coefficient after repetitive heat cycles is causing the Teflon spacer to creep between intake manifold and cylinder head, sometimes causing problems with vacuum or boost lost. It’s worth to note the much lower tensile strength of the Teflon, adding to the problems.